Quick Details

Packaging & Delivery

| Packaging Details: | In rolls, wrapped with anti-rust paper and periphery guard boards, fixed by steel strips, or according to your request. |

| Delivery Detail: | Shipped in 30 days after payment |

Advantages:

It not only has the mechanical strength and easy molding performance of steel plate, but also has good decorative and corrosion resistance of organic materials. Coating adhesion is strong, can maintain long-term color.

Application:

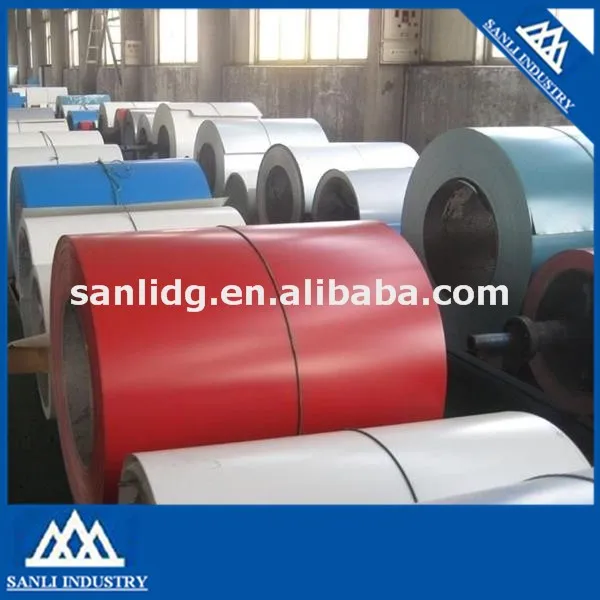

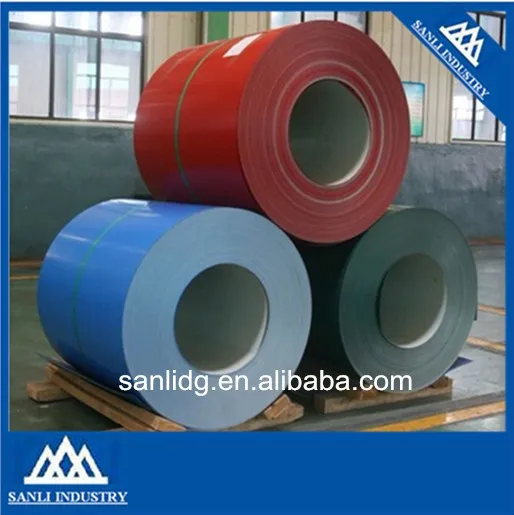

Coated steel coils has light weight, beautiful appearance and good corrosion resistance.

Color steel coils is widely used. With no pollution, excellent weather resistance, corrosion resistance, high processing and other characteristics. Color steel coils is widely used in construction, home appliances, transportation, packaging, machinery processing, interior decoration, medical, automotive industry, etc.. It gives the construction industry, shipbuilding industry, vehicle manufacturing, furniture industry, electrical industry, and so on to provide a new type of raw materials, played with steel on behalf of wood, efficient construction, energy conservation, pollution prevention and other good results.

It not only has the mechanical strength and easy molding performance of steel plate, but also has good decorative and corrosion resistance of organic materials. Coating adhesion is strong, can maintain long-term color.

Application:

Coated steel coils has light weight, beautiful appearance and good corrosion resistance.

Color steel coils is widely used. With no pollution, excellent weather resistance, corrosion resistance, high processing and other characteristics. Color steel coils is widely used in construction, home appliances, transportation, packaging, machinery processing, interior decoration, medical, automotive industry, etc.. It gives the construction industry, shipbuilding industry, vehicle manufacturing, furniture industry, electrical industry, and so on to provide a new type of raw materials, played with steel on behalf of wood, efficient construction, energy conservation, pollution prevention and other good results.

Advantages of Hot Dip Galvanizing

1 low processing costs: costs than the other hot dip galvanized antirust paint coating with low cost;

2 Durable: in suburban environment, the standard hot dip galvanized rust proof thickness can be maintained for more than 50 years without the need to repair; in the urban areas or offshore areas, the standard hot dip galvanized rust layer can be maintained for 20 years without having to repair;

3 The reliability is good: zinc coating and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable;

4 The toughness of the coating: galvanized layer to form a special metallurgical structure, this structure can withstand the mechanical damage in transit and use;

5 A comprehensive protection: plating pieces of each part can be plated with zinc, even in the depression, sharp and hiding place can be fully protected.

6 Save time and effort: zinc coating process than other construction method is more efficient, and can avoid the time required for the installation of the painting on the site.

7 Reliability: specification of hot dip galvanizing general according to BS EN ISO 1461 execution, restrictions the minimum thickness of zinc, so the antirust period and the performance is reliable and predictable.

Sanli Industrial Co., Ltd. is located in Jianhua Industrial Park at Langda Road, Town of Shengfang, Bazhou City. The company was founded in 1995 with 13.8 million RMB of registered capital. Covering 80 areas, it is the key supporting unit approved by Langfang City Commission for Disciplinary Inspection as well as a well-known enterprise among fellow traders in China. In 2003, the company passed ISO9001 international quality certification system. In recent years, the products have gained favorite comments from numerous customers during the marketing.

The company specializes in producing heatronic welded pipes and all types of cold and hot rolling strip steel. We have 11 production lines for heatronic welded pipe, 40 sets of dual-roller rolling mills, and one set of tri-roller rolling mill and one set of four-roller rolling mill. In addition, we also have matching acid rinsing production lines and annealing furnace, mainly producing all types of furniture pipes, circular pipes, shaped pipes and materials for steel sashes with thickness between 0.5 and 2.5, as well as different specifications and types of cold and hot rolling strip steel, so as to meet the needs of different customers. The products are manufactured through advanced technique and strict quality management.

The company specializes in producing heatronic welded pipes and all types of cold and hot rolling strip steel. We have 11 production lines for heatronic welded pipe, 40 sets of dual-roller rolling mills, and one set of tri-roller rolling mill and one set of four-roller rolling mill. In addition, we also have matching acid rinsing production lines and annealing furnace, mainly producing all types of furniture pipes, circular pipes, shaped pipes and materials for steel sashes with thickness between 0.5 and 2.5, as well as different specifications and types of cold and hot rolling strip steel, so as to meet the needs of different customers. The products are manufactured through advanced technique and strict quality management.

没有评论:

发表评论