Quick Details

Packaging & Delivery

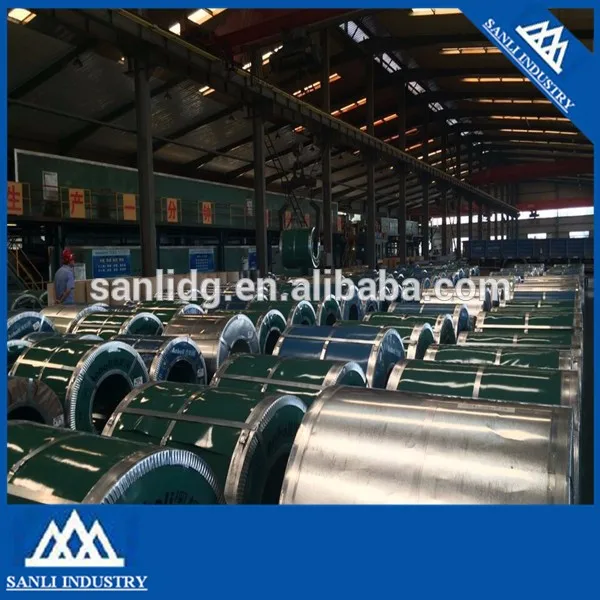

| Packaging Details: | In rolls, wrapped with anti-rust paper and periphery guard boards, fixed by steel strips, or according to your request. |

| Delivery Detail: | Shipped in 7 days after payment |

Cold rolled strip has the advantages of smooth surface, high dimensional accuracy and good mechanical properties. Cold rolled strip due to work hardening, low toughness, but can achieve a better bending strength ratio, used for cold bending springs and other parts.

Widely used in construction machinery, transportation machinery, construction machinery, lifting machinery, agricultural machinery and light industry and other industries of the general structure, cold bending springs and stamping parts.

Widely used in construction machinery, transportation machinery, construction machinery, lifting machinery, agricultural machinery and light industry and other industries of the general structure, cold bending springs and stamping parts.

Advantages of Hot Dip Galvanizing1 low processing costs: costs than the other hot dip galvanized antirust paint coating with low cost;

2 Durable: in suburban environment, the standard hot dip galvanized rust proof thickness can be maintained for more than 50 years without the need to repair; in the urban areas or offshore areas, the standard hot dip galvanized rust layer can be maintained for 20 years without having to repair;

3 The reliability is good: zinc coating and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable;

4 The toughness of the coating: galvanized layer to form a special metallurgical structure, this structure can withstand the mechanical damage in transit and use;

5 A comprehensive protection: plating pieces of each part can be plated with zinc, even in the depression, sharp and hiding place can be fully protected.

6 Save time and effort: zinc coating process than other construction method is more efficient, and can avoid the time required for the installation of the painting on the site.

7 Reliability: specification of hot dip galvanizing general according to BS EN ISO 1461 execution, restrictions the minimum thickness of zinc, so the antirust period and the performance is reliable and predictable.

2 Durable: in suburban environment, the standard hot dip galvanized rust proof thickness can be maintained for more than 50 years without the need to repair; in the urban areas or offshore areas, the standard hot dip galvanized rust layer can be maintained for 20 years without having to repair;

3 The reliability is good: zinc coating and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable;

4 The toughness of the coating: galvanized layer to form a special metallurgical structure, this structure can withstand the mechanical damage in transit and use;

5 A comprehensive protection: plating pieces of each part can be plated with zinc, even in the depression, sharp and hiding place can be fully protected.

6 Save time and effort: zinc coating process than other construction method is more efficient, and can avoid the time required for the installation of the painting on the site.

7 Reliability: specification of hot dip galvanizing general according to BS EN ISO 1461 execution, restrictions the minimum thickness of zinc, so the antirust period and the performance is reliable and predictable.

没有评论:

发表评论